Understanding Flat Face O'Ring Hydraulic Fittings: A Complete Guide

Flat face O'Ring hydraulic fittings play a crucial role in modern hydraulic systems, ensuring reliable fluid connections and preventing leaks. In this comprehensive article, we explore everything you need to know about these fittings, including their design, benefits, applications, and how to choose the right fittings for your specific needs.

What are Flat Face O'Ring Hydraulic Fittings?

Flat face O'Ring hydraulic fittings are specialized components designed to connect hydraulic hoses and tubing in a manner that minimizes leaks and maximizes fluid flow efficiency. These fittings utilize a flat sealing surface, which, when coupled with an O'Ring, forms a robust seal capable of withstanding high pressures and various environmental conditions.

The Importance of Choosing the Right Fittings

When it comes to hydraulic systems, using the right fittings is essential for achieving optimal performance. The quality of hydraulic fittings can significantly impact the efficiency, safety, and longevity of your equipment. Here are some reasons why selecting the right flat face O'Ring hydraulic fittings matters:

- Leak Prevention: Properly designed fittings reduce the risk of leaks, thus saving valuable resources and preventing environmental contamination.

- Improved Flow: These fittings ensure a smooth and uninterrupted flow of hydraulic fluid, which is critical for the efficiency of hydraulic systems.

- Durability: High-quality materials and precise manufacturing of flat face O'Ring fittings enhance the durability and lifespan of the hydraulic components.

- System Safety: Robust fittings help prevent accidents related to hydraulic failures, ensuring a safer working environment.

Design Features of Flat Face O'Ring Hydraulic Fittings

The design of flat face O'Ring hydraulic fittings incorporates several key features that contribute to their effectiveness and reliability:

- Flat Sealing Surface: The flat surface allows for a large contact area, improving sealing performance under high pressure.

- O'Ring Configuration: A precisely fitted O'Ring ensures a tight seal, adapting well to variations in pressure and temperature.

- Material Selection: Common materials include steel, stainless steel, and brass, each selected based on application requirements such as pressure and environmental conditions.

Applications of Flat Face O'Ring Hydraulic Fittings

These fittings find applications in a multitude of industries due to their versatile nature:

- Agriculture: Used in agricultural machinery for hydraulic systems that operate implements such as plows and harvesters.

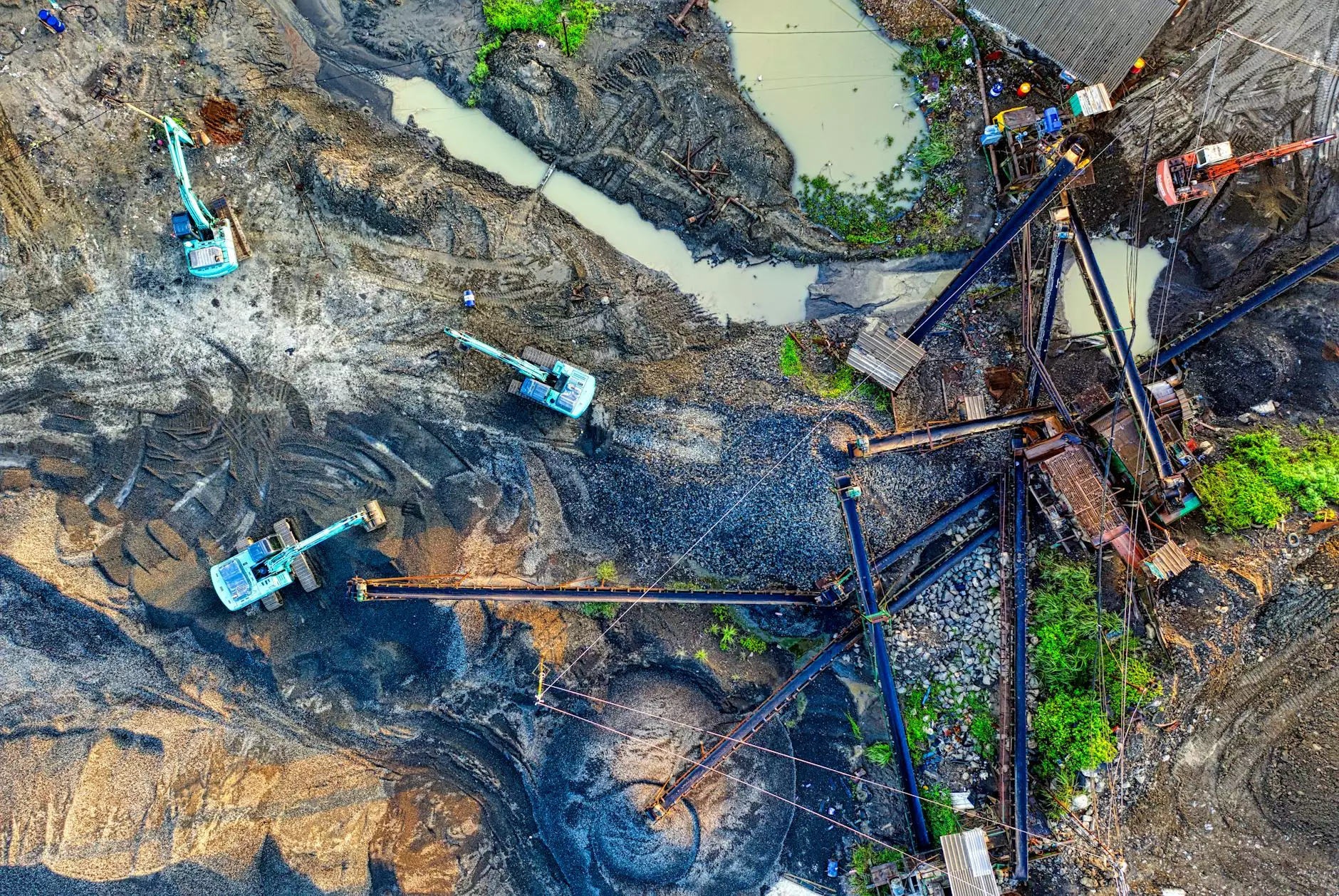

- Construction: Essential in construction equipment like excavators and bulldozers, facilitating efficient power transfer.

- Transportation: Employed in hydraulic braking systems and steering controls in vehicles.

- Manufacturing: Crucial in various manufacturing processes, including material handling and automated systems.

Advantages of Using Flat Face O'Ring Hydraulic Fittings

There are numerous advantages to using flat face O'Ring hydraulic fittings in your hydraulic systems:

- Efficiency: The design promotes efficient fluid transfer, reducing energy loss.

- Compatibility: These fittings are versatile and can be used with different types of hydraulic fluids.

- Ease of Installation: Their design allows for quick and easy connection and disconnection, saving time during maintenance and repairs.

- Customizability: Various sizes and configurations are available to match specific application requirements.

Choosing the Right Flat Face O'Ring Hydraulic Fittings

When selecting flat face O'Ring hydraulic fittings for your applications, several factors should be considered:

- Pressure Rating: Ensure that the fittings are rated for the specific pressure conditions of your system.

- Material: Select materials that are compatible with the hydraulic fluid and the operating environment.

- Size: Choose fittings that match the diameter of your hoses and tubing to ensure proper connectivity.

- Type of Seal: Consider whether a standard O'Ring or a more specialized sealing solution is required for your application.

Common Challenges and Solutions

Despite their robust design, users may encounter certain challenges with flat face O'Ring hydraulic fittings:

- Leakage: Ensure that the O'Ring is properly lubricated and fitted. Replace O'Rings regularly to maintain performance.

- Corrosion: Select fittings made of corrosion-resistant materials if operating in harsh environments.

- Installation Errors: Follow installation guidelines closely to avoid cross-threading or misalignment.

Conclusion: Optimizing Your Hydraulic Systems

In conclusion, flat face O'Ring hydraulic fittings are indispensable components in modern hydraulic systems. Their design, coupled with the advantages they offer, makes them a preferred choice in numerous applications. By understanding the importance of choosing high-quality fittings and how they contribute to the overall efficiency and safety of hydraulic systems, businesses can optimize their operations, save costs, and enhance productivity.

About Fitsch.cn

Fitsch.cn specializes in providing high-quality hydraulic fittings, including a comprehensive range of flat face O'Ring hydraulic fittings. With a commitment to quality and customer satisfaction, Fitsch.cn is your trusted partner for hydraulic solutions. Explore our catalog today to find the right fittings that meet your requirements.

Contact Us

For more information about our products and services, please visit Fitsch.cn or contact our sales team. We are ready to assist you in selecting the perfect hydraulic fittings for your needs!